Quality and Precision: Our Non-Negotiable Standard

Rigorous quality control processes and adherence to industry-leading certifications.

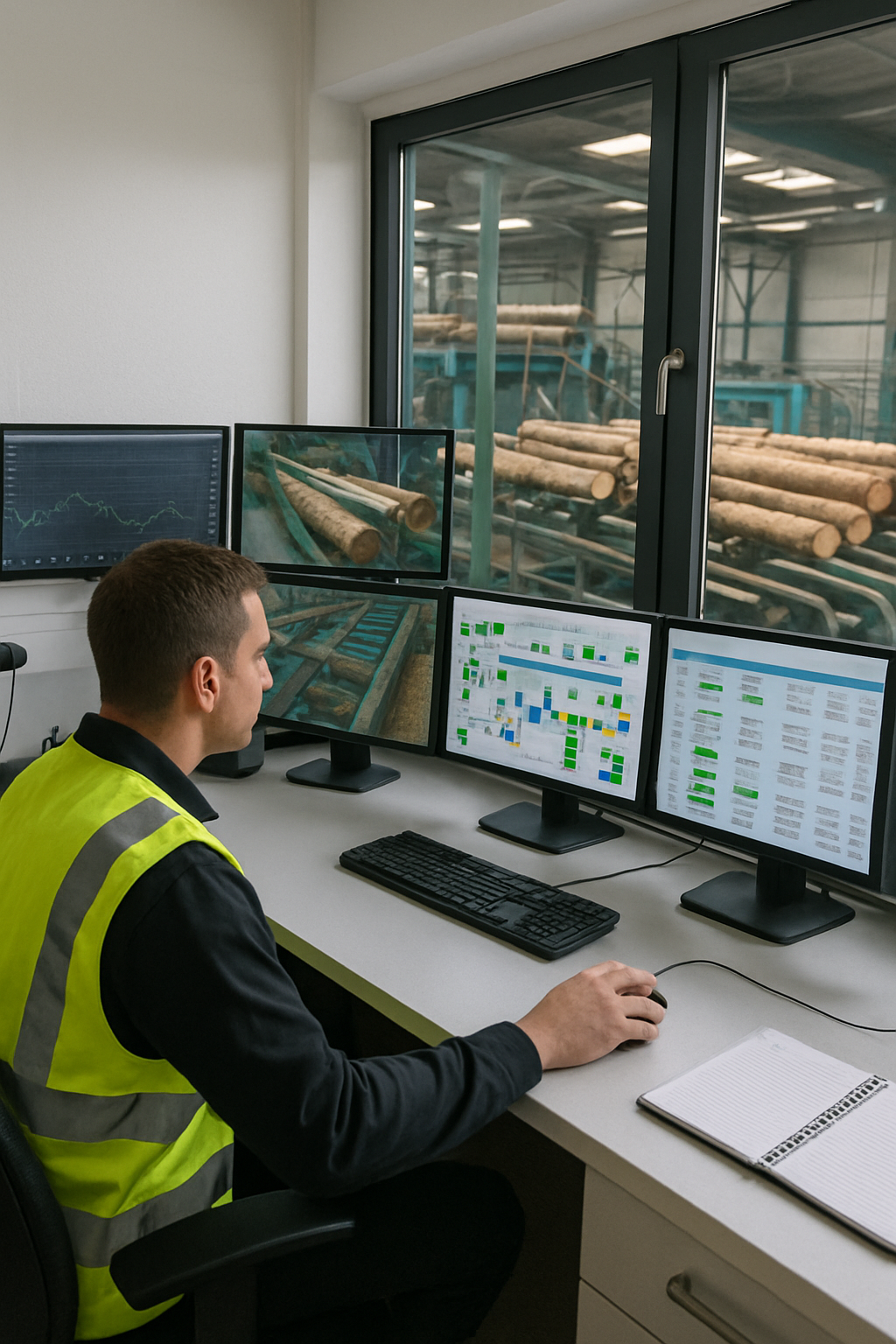

Integrated Quality Management System

Quality at Northern Industrial, LLC is not a final check; it is an integrated process that begins in the log yard and continues through every stage of milling, drying, and finishing. Our Quality Management System (QMS) is designed to ensure **dimensional accuracy**, **consistent grading**, and **optimal moisture content** for every product we ship.

We utilize advanced scanning and measurement technology, coupled with highly trained quality control personnel, to monitor production in real-time. This proactive approach allows us to identify and correct deviations immediately, guaranteeing that our industrial wood products meet the precise specifications required by our customers.

Key Quality Control Points:

- **Log Scaling & Grading:** Initial assessment of raw material quality and volume.

- **Sawing Optimization:** Computer-controlled systems maximize yield and cut accuracy.

- **Kiln Drying:** Continuous monitoring of temperature and humidity to achieve target moisture content (MC).

- **Final Grading & Inspection:** Manual and automated checks for grade, finish, and dimensional tolerance before packaging.

Certifications and Compliance

ALSC/WWPA Compliance

All our lumber is graded and stamped in compliance with the American Lumber Standard Committee (ALSC) and Western Wood Products Association (WWPA) rules.

Sustainable Forestry Certification

We maintain chain-of-custody certifications (e.g., SFI, FSC) to ensure our sourcing meets the highest standards of environmental and social responsibility.

ISO 9001 Alignment

Our internal QMS is aligned with ISO 9001 principles, demonstrating our commitment to continuous improvement and customer satisfaction.

Discuss Your Quality Requirements

Our quality assurance team is available to review your specific material and grading needs.

Request a Quote Today