Our Facilities: Precision and Scale

A vertically integrated operation designed for maximum efficiency and quality control.

The Northern Industrial Mill Complex

Located strategically in the Seattle area, our mill complex is a modern, high-capacity facility that integrates primary log breakdown, kiln drying, and precision planing operations. This vertical integration allows us to maintain strict quality control from the moment the log enters the yard until the finished product is shipped.

Our facility is continuously upgraded with the latest technology, including **optimized scanning and sawing systems** that maximize yield and dimensional accuracy. We prioritize a clean, organized, and safe working environment, which is essential for both employee well-being and product quality.

Key Operational Areas:

- **Log Yard:** Large-capacity, organized storage for raw material, managed with heavy machinery like the **forklift** and log stackers.

- **Sawmill:** Primary breakdown of logs into rough lumber, cants, and flitches using high-speed band saws and circular saws.

- **Kiln Drying:** Advanced kilns ensure precise moisture content control, a critical step for producing stable, high-quality surfaced lumber.

- **Planing Mill:** Precision surfacing and pattern cutting using high-speed planers and moulders.

- **Shipping & Logistics:** Dedicated rail and truck loading facilities for efficient, high-volume distribution.

Technology and Efficiency

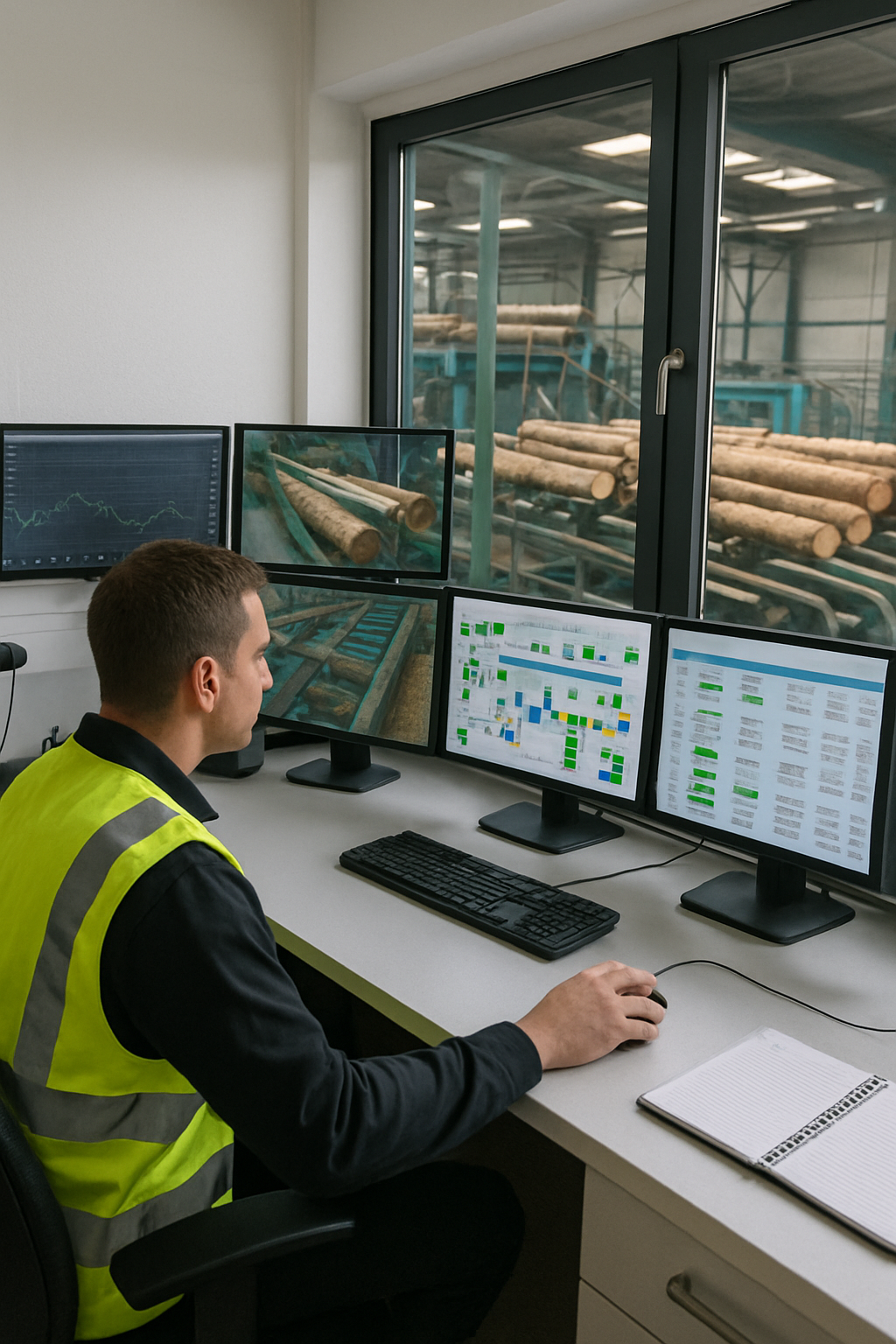

Automated Control

Centralized control rooms manage the entire milling process, ensuring optimal machine performance and minimal human error.

Energy-Efficient Drying

Our kilns utilize advanced heat recovery and often wood-waste biomass to reduce energy consumption while achieving precise moisture specifications.

High-Speed Handling

Automated stacking, sorting, and packaging systems ensure rapid throughput and safe handling of finished products.

See Our Commitment to Quality

Our facilities are the engine of our quality assurance process.

View Quality Standards →